Zmdi-facebook

Zmdi-twitter

Zmdi-youtube-play

Zmdi-instagram

Controleo3 Reflow Oven Controller build kit (open-source)

$152.59

9919

Restocking Fee: No

All returns accepted: Returns Accepted

Item must be returned within: 30 Days

Return shipping will be paid by: Buyer

Country/Region of Manufacture: United States

MPN: Does not apply

Brand: Does not apply

Refund will be given as: Money Back

Featured Refinements: Reflow Oven

Controleo3 Reflow Oven Controller with Oven Build Kit

If you only want the Controleo3 controller, please look at

this

listing.

Follow the step-by-step build instructions here:

(Oops, eBay doesn’t allow links. Do an Internet search for “Whizoo Controleo3”)

Built on a solid foundation

ControLeo2 was a wonderfully successful product, selling hundreds to customers world-wide. They’ve been used to control ovens large and small, convection, hot plate or conveyor belt. Such was the power of this well-designed controller and open-source software.

We received a lot of feedback from customers. Our customers range from hobbyists reflowing exciting projects in their garages all the way to large corporations doing prototyping of next-generation products while keeping tight control over deadlines and intellectual property. We’ve also had a lot of feedback from industry experts, commenting on the controller, our build guide and our software. We have been making continuous changes to our web site and build kit to reflect all this expertise.

Giant leap forward to Controleo3

Controleo3 was designed to address ControLeo2’s shortcomings, and extend the controller’s capabilities far into the future. It retains ControLeo2’s strengths like ease-of-use, flexibility and openness but dramatically increases performance and usability.

4-inch 480 x 320 color touchscreen

Processor is 12 times faster

10 times more memory and 40 times the storage

Supports 6 outputs (up from 4)

Support for up to 28 profiles

PID support, with intelligent tuning

SD card support for log files, screenshots and reflow profiles

Upgraded thermocouple IC has line-voltage filtering

Hardware is more robust (dare we say idiot-proof?)

The challenges of building a reflow oven

Lead-free solder requires higher temperatures than leaded solder. Take a look at a typical reflow curve for lead-free solder:

An important part of the reflow curve is the maximum temperature of 255°C (480°F). It is difficult to build an oven that is capable of reaching those temperatures in such a short duration. However, another important number is the rate-of-rise of temperature at the higher temperatures. At those temperatures it becomes increasingly difficult to achieve the required rate-of-rise without running the heating elements at full blast. You run the risk of damaging sensitive components if the reflow takes too long, and you can create hot spots (damaged components) and cold spots (no solder reflow) if the elements glow red hot.

There are a lot of other problems that can occur if the reflow profile isn’t followed. Components can be damaged from thermal shock or cracking, solder paste can splatter which can lead to voiding in array type packages, and the solder paste could oxidate or the flux not fully activate. If the maximum allowable temperature of IC’s is exceeded, it can damage the internal dies of components and foster intermetallic growth leading to shortened MTBF (mean time before failure) numbers. The time-above-liquidus and cooling rate also affect the quality of the resulting solder joint.

What makes Controleo3 the best reflow oven controller?

The Controleo3 controller and the oven built in the build guide (on the Whizoo web site) should be considered

top-of-the-line

. A lot of engineering and experience has gone into making the Controleo3 reflow oven, and there are currently more than 1000 customers world-wide using either ControLeo, ControLeo2 and the latest Controleo3.

If you are only doing small boards and using leaded solder paste you can get away with a less-capable controller and poorly insulated oven. But how much is your time worth? What is the value of the components you plan to use? What is the turn-around time to order new boards or components when they get heat-damaged? Do yourself a favor and build yourself a great reflow oven. Do it once, and do it right!

Controleo3’s advantages:

Six outputs

Control convection fans, cooling fans and heater elements individually.

Better heat distribution

Having control over individual heating elements allows you to keep heat away from sensitive components.

Hot-spot elimination

Intelligent software manages element on-time, reducing hot and cold spots in the oven.

Better heat direction

Ability to specify if heat comes from the top or bottom, depending on the reflow phase.

Better current management

Elements are turned on and off independently eliminating the current spikes common in single-relay

controllers.

Ready-to-run

No programming needed. Just configure the fans and elements your oven has and the software will do the rest.

Profile support

Support for up to 28 user-defined profiles.

Intelligent PID tuning

PID tuning is done automagically during a learning run.

Proven hardware

Controleo3 is based on the Arduino Zero. It expands the capabilities of ControLeo2, which

was field-tested for years.

Open-source

Controleo3 is fully compatible with the Arduino programming environment, and runs Arduino Zero sketches. A library and “Reflow Wizard” software for Controleo3 has been posted to GitHub.

Reflow Wizard

Intelligent software makes it easy to get your oven up and running. Ensures consistent results, run after run.

Reflow feedback

If you connect Controleo3 to a computer you can track the reflow progress and get data to plot a reflow

temperature graph. Support for SD card logging will be added soon.

Servo support

Supports industry-standard servos, so the oven door is automatically opened at the end of the reflow cycle

to start the cooling process.

Baking

The baking mode supports a full range of temperatures, and a duration of up to 168 hours.

Build guide

Our comprehensive build guide (on the Whizoo web site) takes you step-by step through building your own oven.

The alternatives

Cheap China reflow oven (T962/T962A/T962C)

These ovens have infrared elements located directly above the boards. There are no heating elements below the boards.

Infrared is absorbed at different rates, so expect darker components to heat up much quicker than lighter ones.

The oven does not conform to the J-STD-020 reflow standard. Specifically, it fails to meet requirement 3.2.2: “It is required that this equipment use IR to heat only the air and not directly impinge upon the SMD Packages/ devices under test.”

All the heat comes from the top. Imagine trying to reflow a microcontroller – the black microcontroller will absorb a lot of the infrared heat while shading the PCB underneath it.

Oven with single ON/OFF control

You can build an oven with a single ON/OFF relay controlling power to the oven, but there are drawbacks:

The top element is on as much as the bottom one. You cannot control heat direction.

No control over the convection or cooling fans

Current spikes as all all elements are turned on or off

Hot plate

Here all the heat comes from the bottom, which is great for keeping heat away from sensitive components. Unfortunately:

Lead-free reflow is not possible. You’ll burn the PCB long before the solder reflows.

No good automation means you need to keep a close eye on the reflow.

How do you follow the recommended reflow profile?

Reflow Wizard software

Controleo3 ships with the “Reflow Wizard” software installed. The software is open-source. It is being

continuously updated

and your Controleo3 is

user-upgradeable

.

A lot of work was done on optimizing the driver level software to make sure Controleo3 is quick and responsive. For example, the screen writing software was optimized, and then optimized again. The result is spectacular – every pixel on the 480×320 screen can be written to in the blink of an eye!

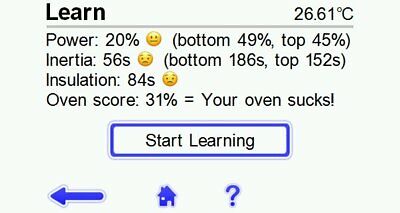

Controleo3 has a brand-new “learning mode” to support PID. It takes a fixed amount of time (around 1 hour) to run. It measures and scores various oven performance metrics, and uses this information to support a smart PID algorithm. You can read more about it on the Whizoo web site.

Controleo3 has a powerful and flexible language to create profiles. Profiles are created on your PC and then loaded onto Controleo3 using a SD card. You can read more about it on the Whizoo web site.

Here’s a look at the user interface. You can appreciate the responsiveness and get a good feel for how easy Controleo3 is to use and configure.

The software has been released as

open-source software

. It will be

continuously updated

and your Controleo3 is

user-upgradeable

.

Step-by-step build instructions

Complete step-by-step instructions for building your own reflow oven can be found on the Whizoo web site.

Controleo3 is open

There is no need to program Controleo3 at all, but if you’re a software guru you can tinker to your heart’s content. We’ve open-sourced all the software we’ve written for Controleo3, including the Reflow Wizard. The software consists of a single Arduino library that controls all of Controleo3’s functions, as well as the Reflow Wizard program. You can find everything on GitHub (do an Internet search for “GitHub Controleo3”).

Controleo3 uses the standard Arduino environment. The library should be installed into your Arduino environment using the instructions found on the Whizoo web site. The single Controleo3 library gives you access to all of Controleo3’s functionality. Installing the library also installs all the sample code we’ve written for it.

In Arduino, select the board as “Arduino Zero”. Your sketches can then be sent to Controleo3 using its micro-USB port.

Controleo3 is expandable

Controleo3 provides both 5V and 3.3V (max 80mA) to power additional components. Output 6 is a microcontroller pin and can be used as either input out output. You can also tie into the SPI bus used by other components, like the MAX31856 thermocouple IC.

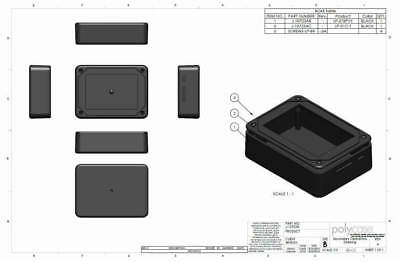

Controleo3 enclosure

Controleo3 uses a quality off-the-shelf flame-retardant ABS plastic enclosure with a textured finish. The holes are CNC machined to perfectly fit Controleo3. The result is a high quality, tight fitting case that looks very good. We are thrilled with this enclosure.

Controleo3 specifications and features

Atmel ATSAMD21J18A-AU microcontroller (Arduino Zero)

32-bit ARM Cortex M0+ core at 48 MHz

256 KB Flash memory

32 KB SRAM

Custom boot loader (turns relays off during boot)

1 MB flash for storing preferences and profiles

Support for full-size SD cards up to 32GB

4″ 480 x 320 color touchscreen display

6 relay outputs – relays are connected using screw terminals or the 6-pin relay header (4 outputs, +5V, GND). The outputs provide up to 220mA at 5V. The outputs support connections to solid-state relays (SSRs) or

mechanical relays

Buzzer – 80db at 10cm

ABS plastic case – custom fit, flame-retardant (UL94-5VA)

MAX31856 thermocouple with line-voltage filtering

Built-in servo support

Input voltage: 5V

The USB port should only be used for software updates and debugging. The USB port does not power the buzzer, the servo nor the relays

The servo is the largest current draw. We recommend using a 2000mA power supply

Reverse-polarity protection on power terminals, and current protection on outputs

What you will get

Controleo3 Reflow Oven Controller

ABS enclosure with UL94-5VA flame rating

Low-mass K-type thermocouple

Enclosure screws

1/4″ Braided sleeving (20″ of red, 10″ of black)

Rubber grommet (3/8″ ID, 5/8″ OD)

1GB SD card

DEI Reflect-A-Gold insulation (2″ x 6 feet)

DEI Floor & Tunnel Shield II insulation:

10.5″ x 8″ (1 piece)

10.5″ x 6″ (2 pieces)

1″ x 1″ used as tray spacers (2 pieces)

8″ x 24″ of 1/4″ ceramic fiber blanket (8 lbs. / cu. ft.)

High-temperature silicone glue (3 Oz. = 85g)

18″ of Nomex high-temperature gasket to seal the oven door

Three 25A 380VAC Solid-state relays (SSR’s)

100mm x 100mm x 0.5mm thermal silicone pad

5052-H32 Aluminum sheets

8″x10-5/8″ x 1/32″ with 1/4″ flange for PCB tray

6″ x 6″ x 1/16″ with 1″ flange to mount SSR’s

1 1/2″ x 3″ x 1/32″ for attaching Controleo3 to the oven chassis

1/2″ x 3″ x 1/32″ for the oven door servo

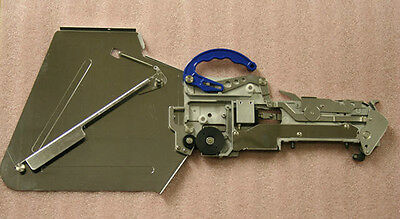

Servo kit

Powerful MG996R servo to open the oven door

Custom servo mounting bracket

Custom “bird’s beak” servo arm

Aluminum servo disk with four M3-.5x5mm phillips screws

Miscellaneous servo hardware, including mounting screws

5V 2A power supply

Stainless steel resistive heating element. Either

350W@110V (400W@120V) or

450W@220V (535W@240V)

(leave a message if you want this one)

Two 3/16″ x 1 1/2″ eye bolts with locking nuts

Ten #6-32 x 1/2″ Phillips truss head machine screws with locking nuts

Eight #4 x 5/16″ Phillips pan head sheet metal screws

30″ of 18 gauge 4-conductor wire

20″ of 18 gauge high-temperature silicone wire

Selection of zip ties

Heat shrink tubing (10mm and 6mm)

Six ring terminal crimps, two female spade crimps and a butt connector

Discount coupons

Buy with confidence – eBay member since 1999. 100% positive feedback!

Click

here

to see my feedback for everything I’ve sold.